Our Machinery Facilities

Plasma Cutting Machine (1 No.)

Capacity: Cuts up to 50 mm thick plates.

Application: Precision shaping of complex components.

Gas Cutting Machines (3 No.’s):

Ideal for straight cuts and beveling MS/SS plates.

Forming & Bending

Plate Bending Roller (1 No.):

Capacity: Forms plates up to 14 mm thick.

Application: Cylindrical shells for vessels/tanks.

Press Brakes:

For bending dished ends, cones, and structural parts.

Welding & Fabrication

TIG Welders (2 No.’s):

For high-precision, spatter-free welds (SS/exotic alloys).

MIG Welders (2 No.’s):

High-speed welding for long seams.

ARC Welders (5 No.’s):

Versatile welding for all positions and materials.

Certified Welders:

Trained to ASME standards for critical joints.

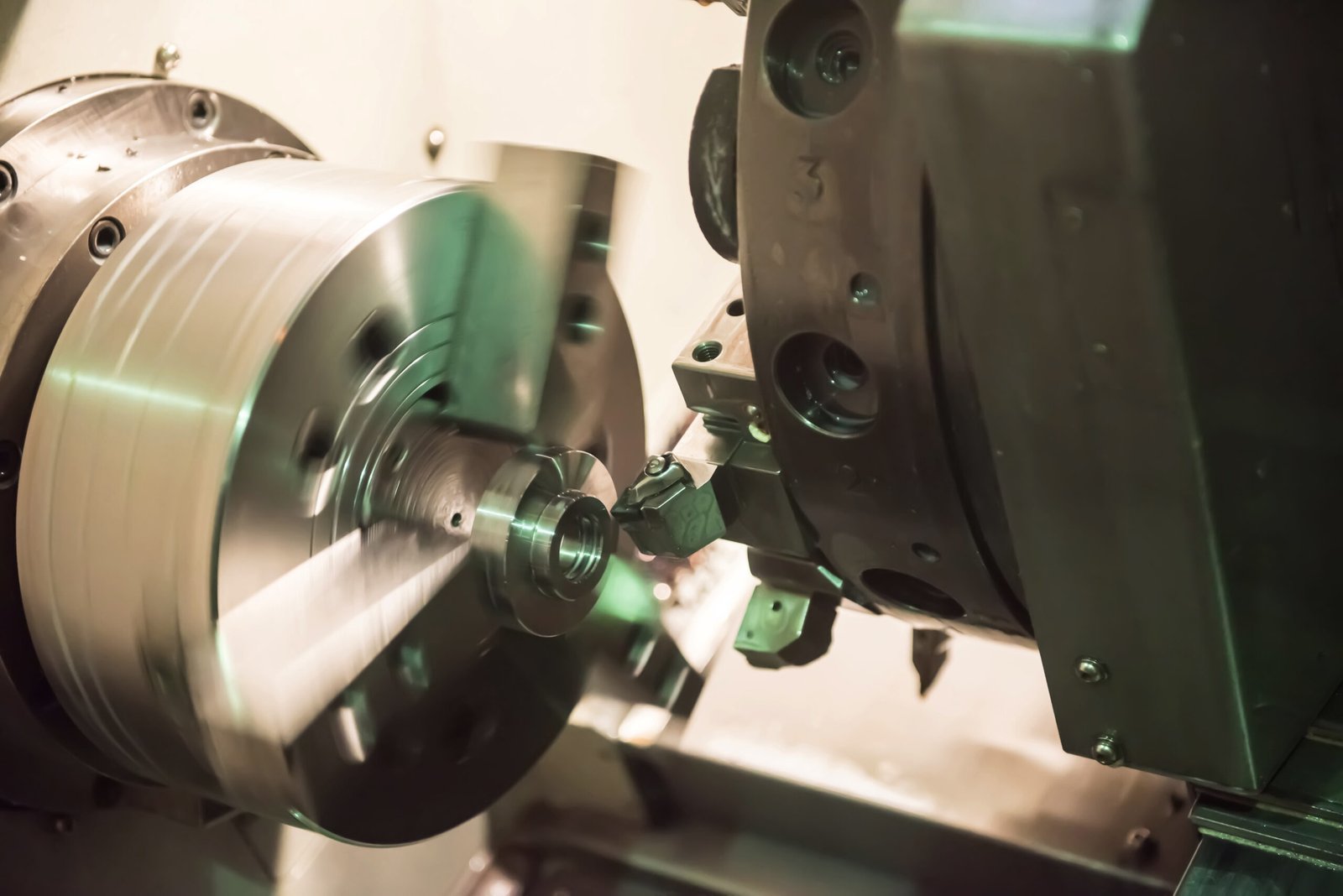

Machining & Drilling

Radial Drilling Machine (1 No.):

For precise hole patterns in large fabrications.

Magnetic Drilling Machines (2 No.’s):

Capacity: Drills up to 40 mm diameter holes.

Broach Drilling Machine (1 No.):

Capacity: Drills up to 32 mm diameter holes.

Application: Nozzle openings in vessels/tanks.

Horizontal Lathe (1 No.):

For machining custom fittings/shafts.

Finishing & Surface Treatment

Grinding Machines:

AG-7 (5 No.’s), Straight (4 No.’s), Bench (1 No.).

Buffing Machine (1 No.):

Mirror finishing for GMP/hygienic applications.

Air Compressor for Painting (1 No.):

For anti-corrosion coatings.

Hydra Crane – 14MT (1 No.)

Testing & Quality Control

In-House Testing:

Hydrostatic Test Pumps

Pneumatic Testing Kits

Dye Penetrant Test (DPT) Kits

Partner NDT Services:

Radiography (RT)

Ultrasonic Testing (UT)

Magnetic Particle Testing (MPT)